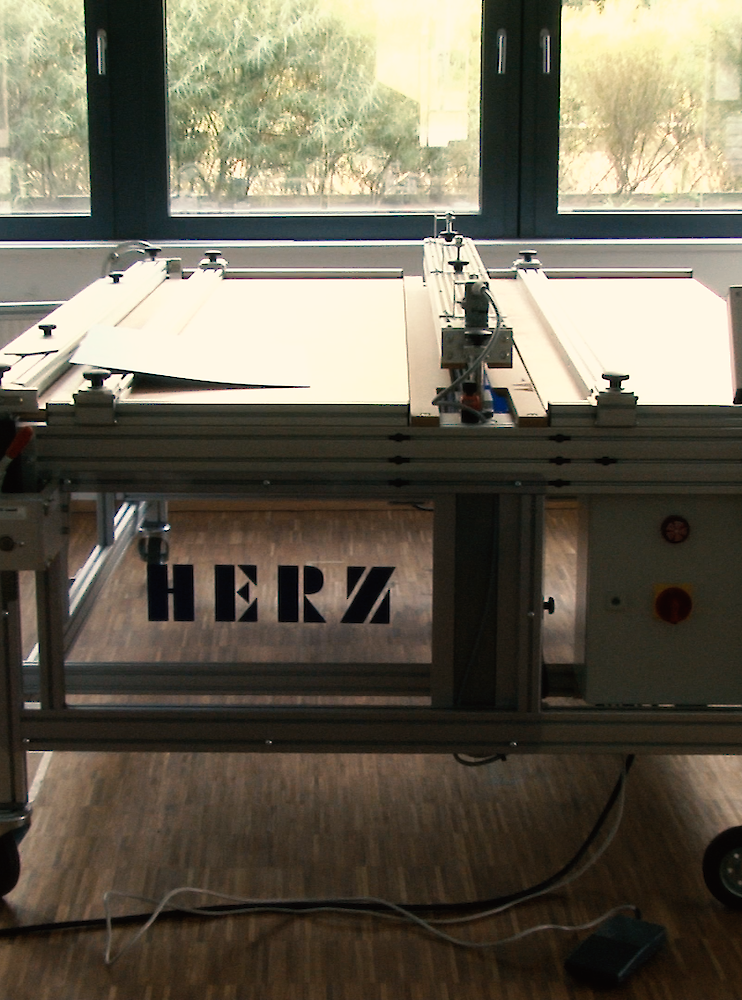

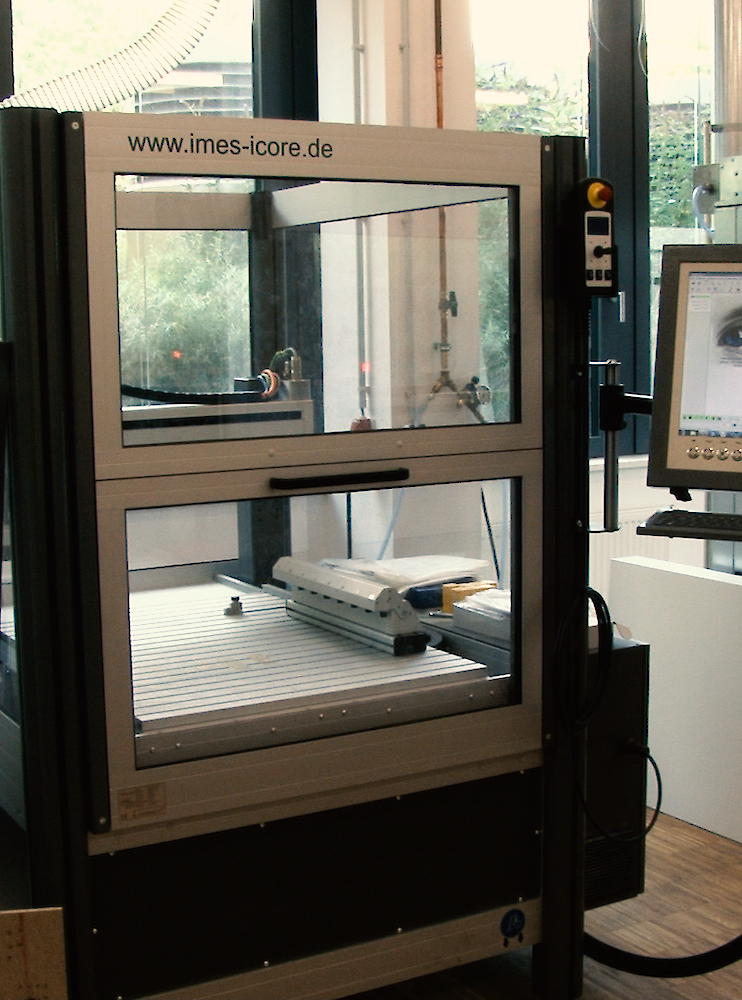

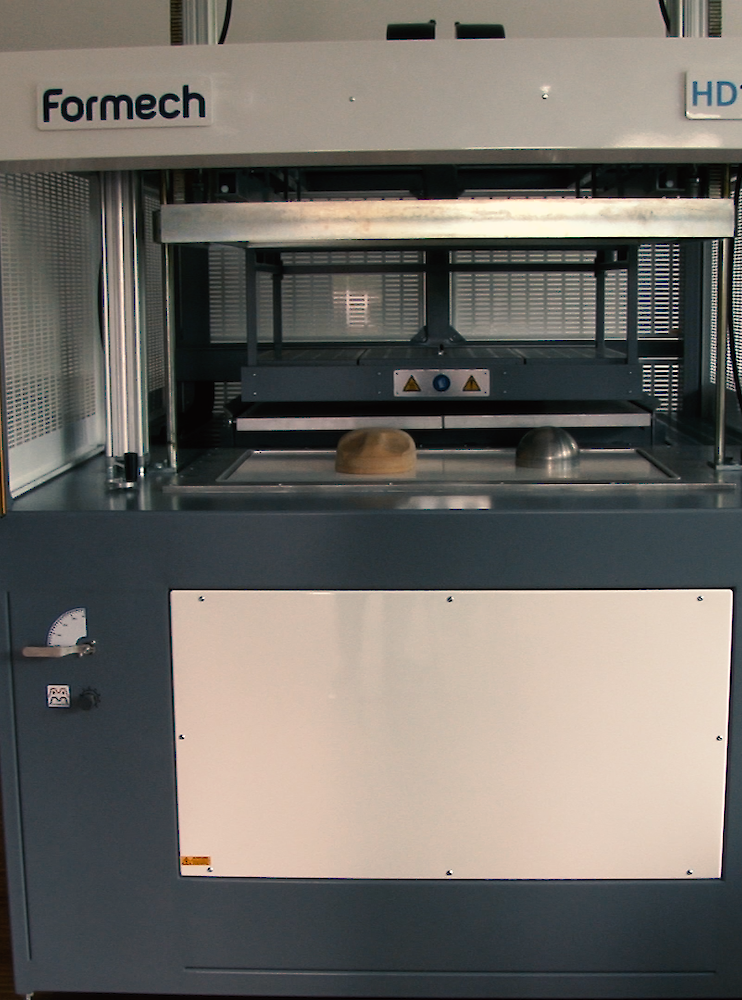

The plastics workshop offers various options for processing different types of plastic. In addition to machines for forming sheet material (plastic bending and folding machine and vacuum thermoforming machine), there is a 3-axis CNC milling machine for PU foam sheets and two laser cutters that can be used to cut and engrave acrylic, polystyrene, and several other plastics, as well as other materials such as textiles, leather, felt, etc. Wood can also be processed with another 3-axis CNC milling machine.

Information for getting started

Laser cutting: You can use the laser during the ID workshop's opening hours. Please contact Thorsten Poppe for more information.

To use Laser 1 (Trotec), bring an Illustrator file (saved for CS6) in "RGB color" document color mode on a USB stick. The paths must have a contour of 0.01 pt and be red (255; 0; 0) for cutting and black (0; 0; 0) for engraving. Areas to be engraved must be filled with black (0; 0; 0). There must be no groupings or guides in the document! For laser cutting with Laser 2 (BRM), bring a .dxf file with ungrouped paths on a USB stick. Different cuts and hatching can be distinguished by different layers.

To cover the costs of wear parts, laser cutting costs money, which can be paid for with your student ID. Standard materials such as acrylic glass, HDF, and plywood can be purchased from Reinhold Heming or brought with you. If you want to laser cut plastic that you have brought with you, you must present a data sheet.

CNC milling: CNC milling requires an STL file, which must first be checked for millability by Philipp Steffens or Lukas Koschorreck. Once the file has been approved, take it and the milling material to Thorsten Poppe.

Other: Thorsten Poppe and Markus Weiß are responsible for the vacuum thermoforming machine, plastic bending and folding bench, and edge polishing machine.